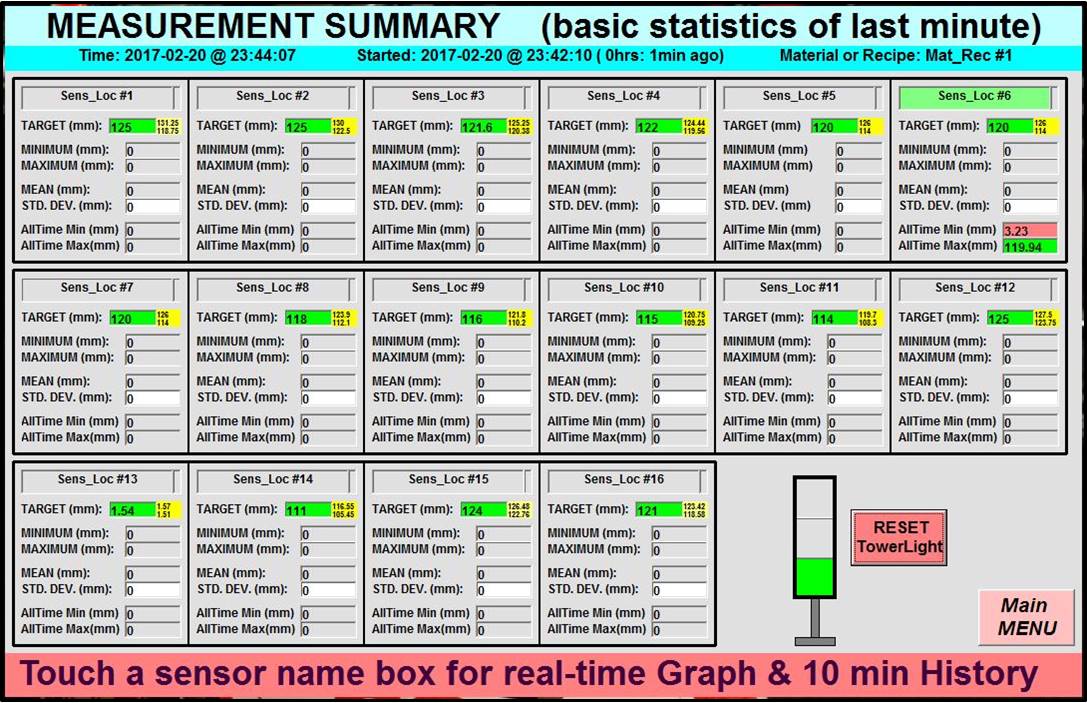

After successfully performing a machine changeover, the user has the ability to monitor each adjustment location's current setting. The main screen of the telemetry mode displays all 16 wireless sensors and machine status via stack beacon lights.

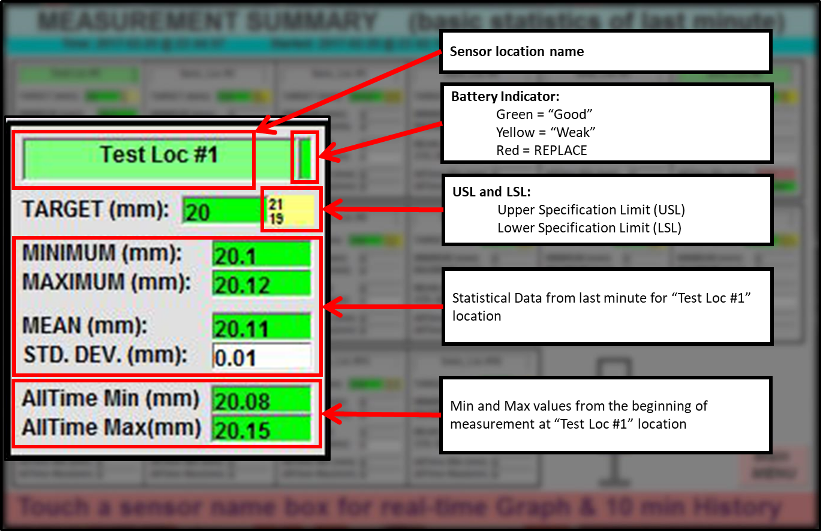

Each cell of the 16 wireless sensors shows the sensor location name, battery indicator, target position distance, upper and lower specification limit, last minute statistical data and all-time min/max for that location.

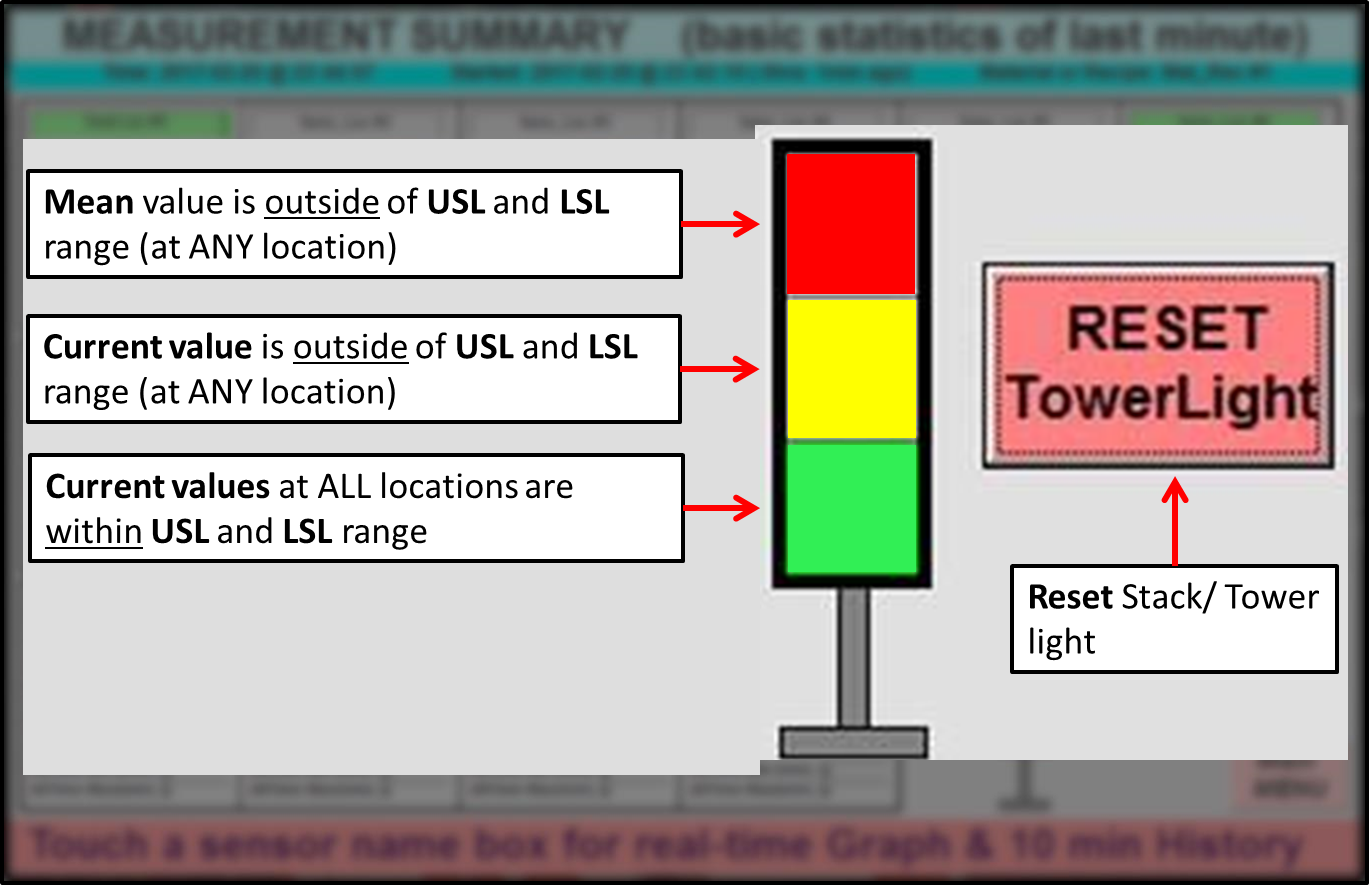

The telemetry mode also shows the status of the wireless stack beacon light. If all 16 sensors are within tolerances, the beacon light is green. If a sensor deviates from the tolerance range, the beacon light will lit yellow. If a sensor has been out of tolerance for more than 60 seconds, the beacon light will be lit red and will remain red until manually resetted.

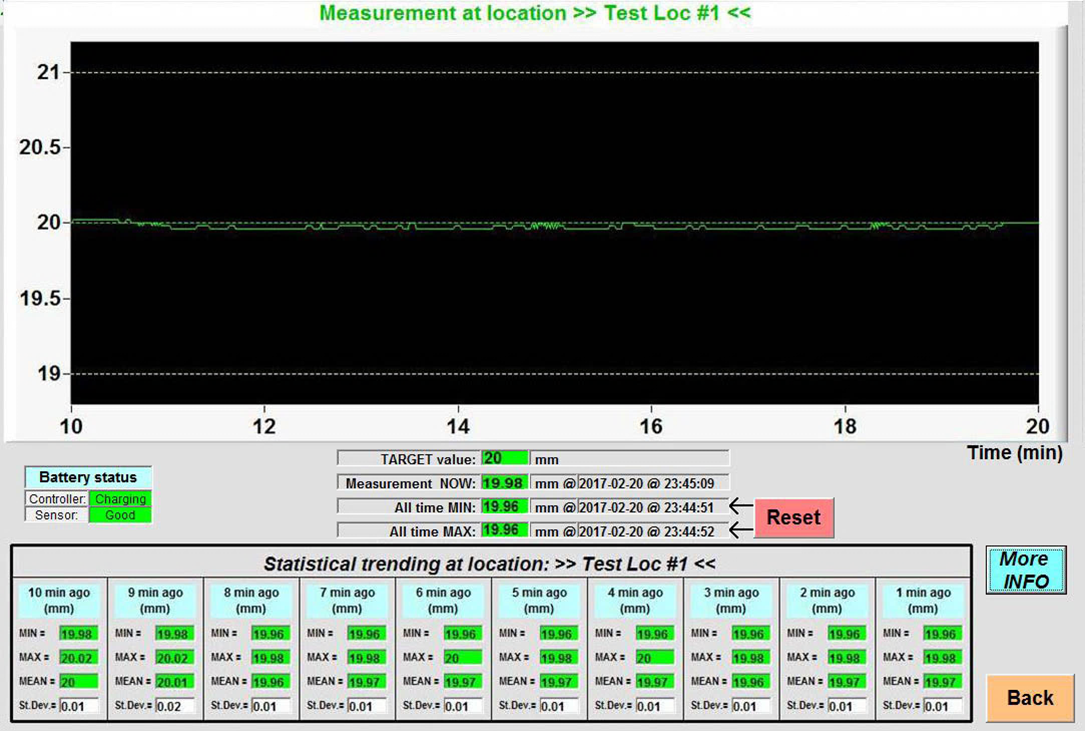

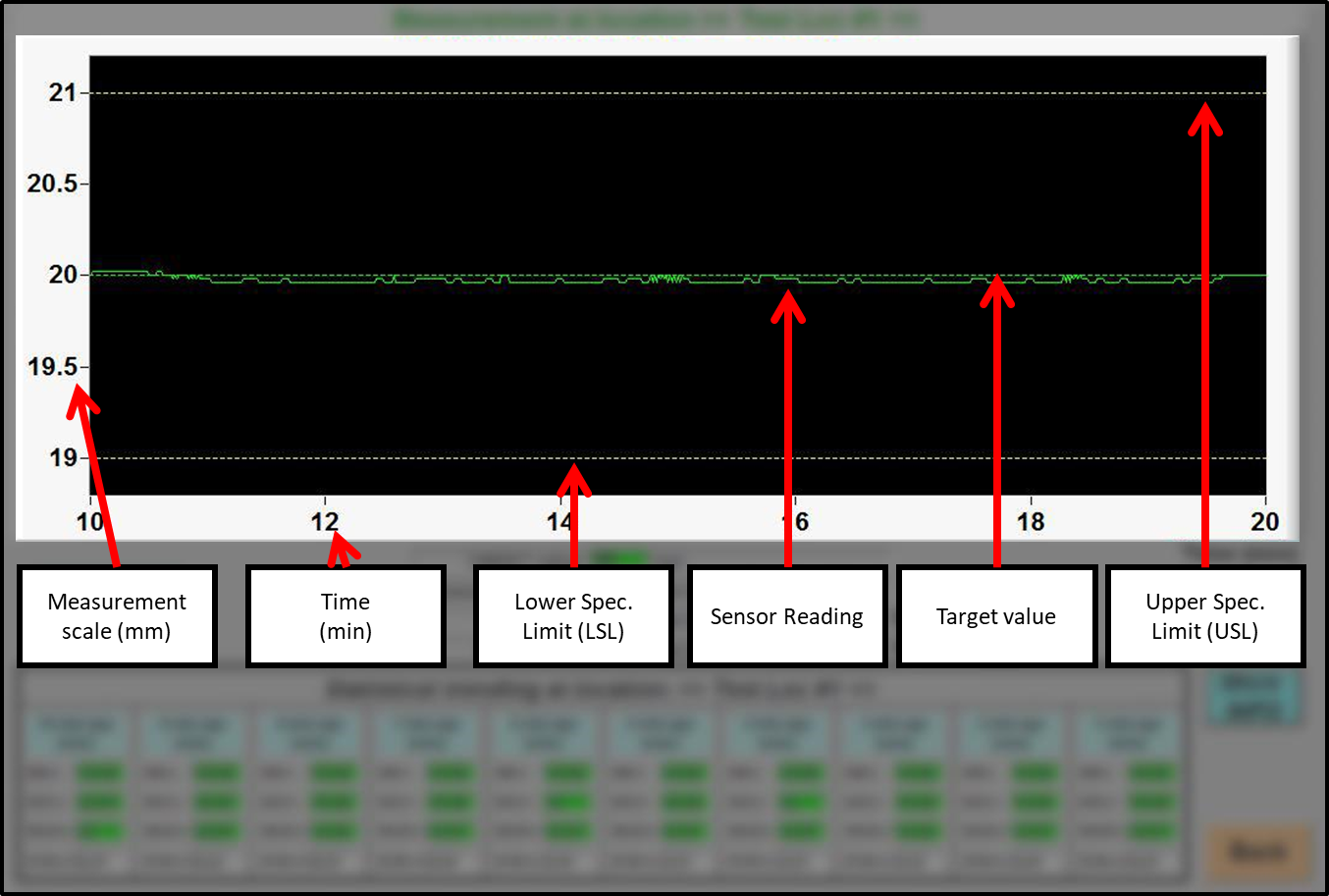

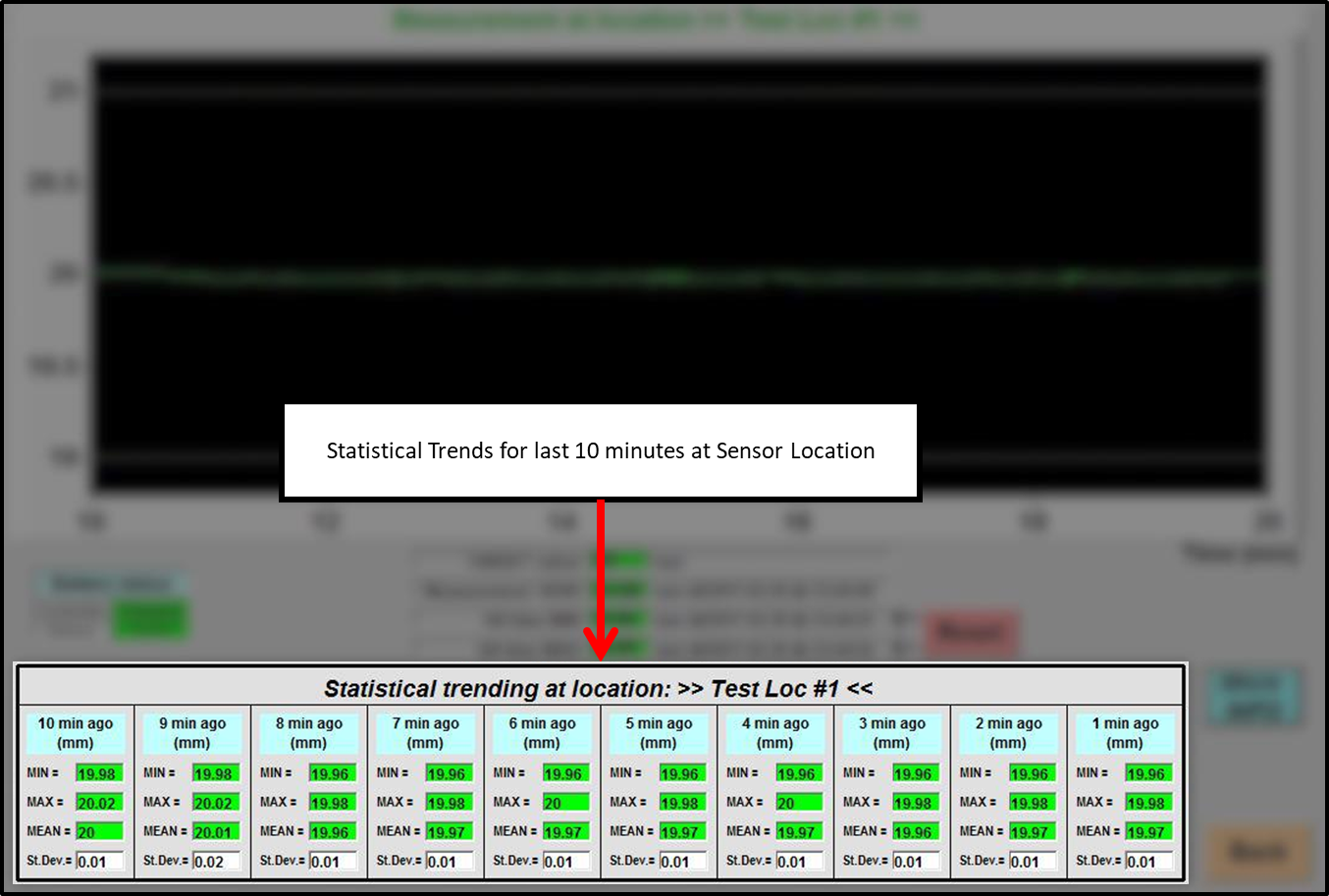

Clicking on the sensors cell will provide the user with a graphical display of recorded values along with statistical trending data from the past 10 minutes of operation.