Goal: Develop solutions to provide interactive operator guidance and enable process data acquisition to diagnose / solve issues in the manufacturing environment.

Manufacturing Improvement Devices, Inc. (MID) is poised and capable of developing innovative electronic solutions to enable lean manufacturing initiatives. We offer manufacturing facilities and original equipment manufacturers (OEMs) cost-effective, turn-key tools solutions for notorious manufacturing problems.

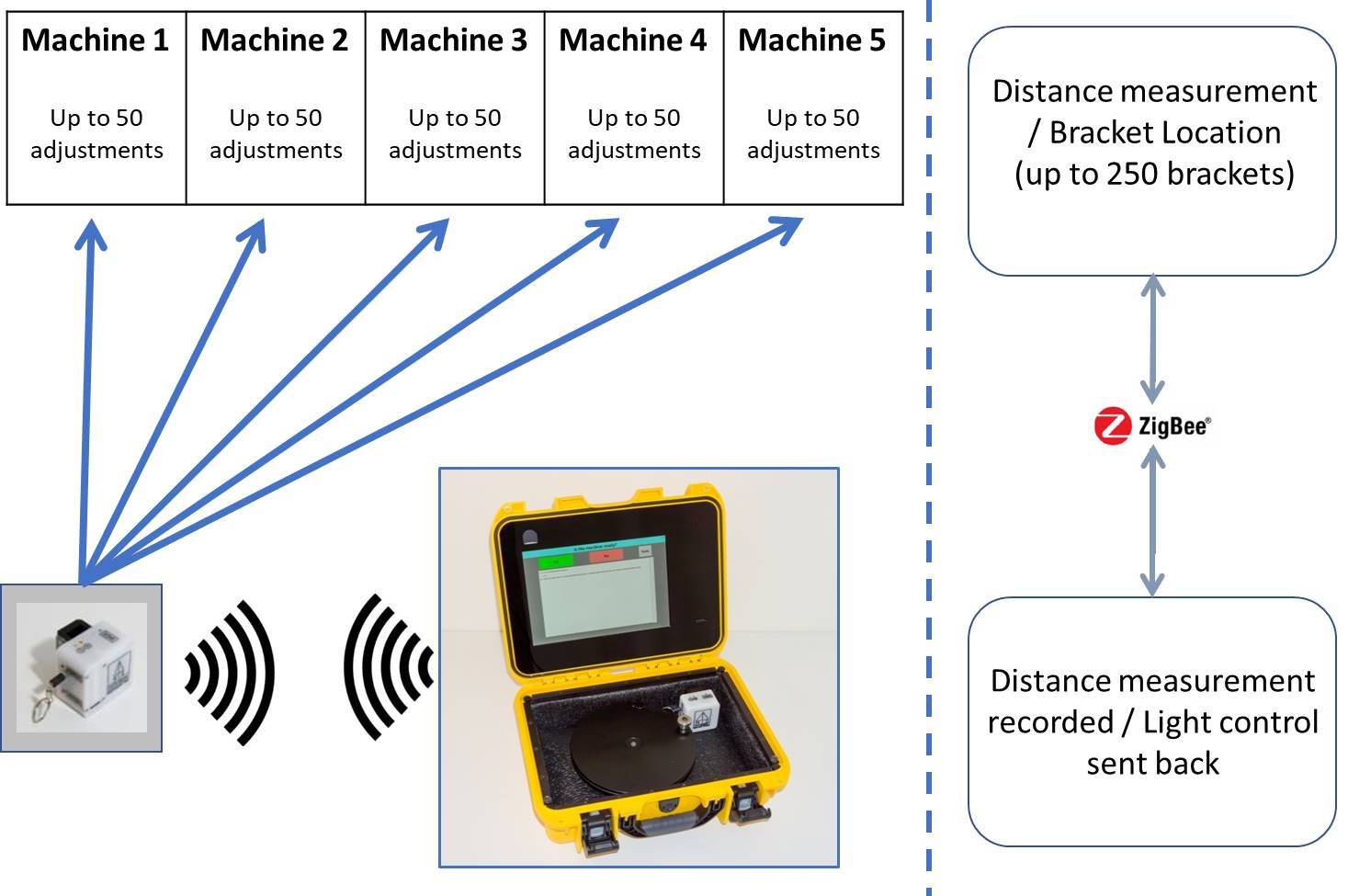

MID’s wireless tools provide operators with guidance to perform their changeover tasks flawlessly as well as enabling “health monitoring” and “predictive maintenance” through data analysis.

MID tools and solutions fully adhere to Industry 4.0 guidelines to maximize both manufacturing predictability and productivity. Efficiency of human assets, as well as productivity of a machine is optimized by:

All MID tools and solutions are fully independent from IT infrastructure on the factory floor and can be easily deployed on any old or new machine.

Changeover Tool (COT)

Changeover & Telemetry Tool (CTT)